SPRING SALE: Receive $100 Off Per Container

The Truth About “New” Containers in Marketplace Advertising

Are you really getting a new shipping container? The facts might surprise you.

Understanding the Difference Between Used vs. New Shipping Containers

When considering purchasing a shipping container, understanding the difference between "used" and "new" is crucial. A common misconception is that there are "new" shipping containers available in North America. In reality, all shipping containers are manufactured in China and brought to North America as part of the global supply chain. Once they arrive and are emptied, they are sold as "new," but in the industry, these are technically referred to as "one-trip" containers.

The Truth About "New" Shipping Containers

If you are in the market for a container, do not be misled into paying a premium for what is advertised as a "new" shipping container. The term "new" can be misleading since all containers arriving in North America have already been used for at least one shipment. Instead, these "one-trip" containers are in pristine condition but come at a higher price than used alternatives.

While it would seem logical to spend more for a new car or new pair of shoes over gently used, we encourage you to research the provider and understand that you in fact are NOT buying a new product. It has been packed and shipped from China and spent time at sea.

Why Buy Used Containers from Eveon?

At Eveon, we specialize in selling only used or decommissioned shipping containers. These containers have lost their certification for international trade but remain highly functional for secure, strong, and modular storage solutions.

- Affordability: Used shipping containers are significantly more cost-effective than "one-trip" containers, making them a budget-friendly solution for storage or repurposing projects.

- Durability: Having been trusted at sea for years, these containers are built to withstand harsh conditions. Even after retiring from global trade, they have decades of land-based usability left in them.

- Eco-Friendly Choice: Opting for a used container contributes to sustainability by repurposing existing materials rather than requiring the production of new ones.

- Immediate Availability: Since used containers are readily available, you can acquire and put them to use much faster than ordering a "one-trip" unit. Eveon promises to only sell what we have access to, we will never sell what is not able to ship within days.

Promoting Circular Economy

Aside from some of the obvious benefits, buying a used shipping container instead of a new or one-trip container significantly supports the circular economy by extending the shipping containers lifecycle and reducing demand for new raw materials. Reusing containers minimizes waste, lowers carbon emissions associated with manufacturing and transportation, and decreases energy consumption compared to producing new steel containers. This approach aligns with sustainable strategies and corporate practices by preventing unnecessary scrapping and encourages repurposing durable materials for various applications, such as storage. By choosing a second-hand container, businesses and individuals contribute to a more resource-efficient system that prioritizes reuse over continuous production and disposal.

Eveon: Your Trusted Source for Used Containers

Eveon ensures that every container sold meets industry standards, offering secure and robust storage solutions. Whether you need a container for business storage, onsite branding, personal use, or even a creative repurposing project, buying used from Eveon provides affordability, durability, and peace of mind.

Don't overpay for a so-called "new" container—choose the smart, cost-effective, and sustainable option by purchasing a used container from Eveon today!

Frequently Asked Questions

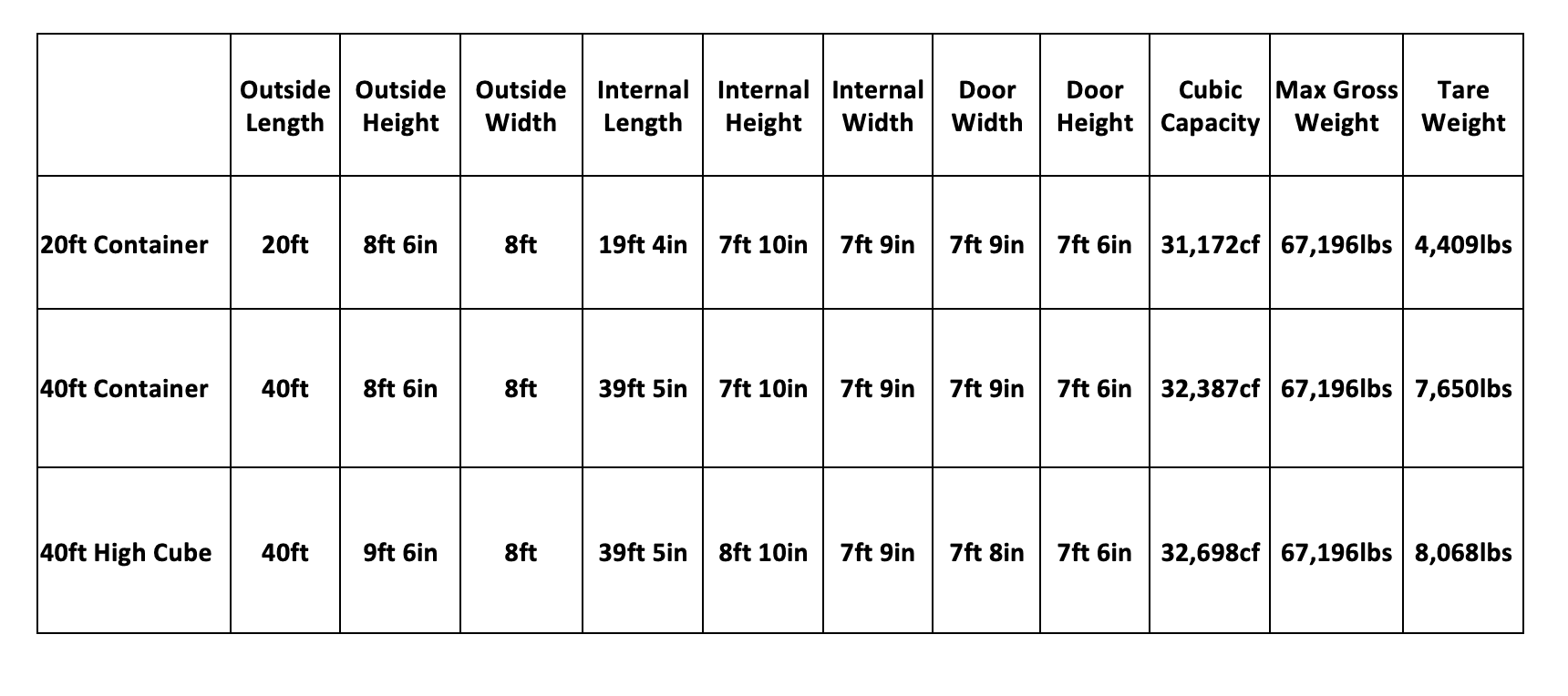

Eveon Containers come in three universal sizes. They all have lengths (externally) of 20ft or 40ft and 8ft in width as standard. The height of a container will be 8ft 6” for the standard containers. The height of a High Cube (HC) will have an additional foot to be 9ft 6”.

Shipping containers, made from robust Corten steel, undergo meticulous manufacturing steps including cutting, welding, and protective measures to ensure strength and durability during transportation and storage.

Shipping containers are manufactured using durable steel materials. The process commences with a large sheet of steel that is subsequently cut into smaller sections. These sections are then corrugated and welded together to enhance their strength and structural integrity.

The majority of shipping containers are constructed from a type of steel known as Corten steel, also referred to as "weathering steel". Corten steel is an alloyed steel that contains other metals which react when exposed to air and water. This reaction leads to the formation of a protective layer of oxidation that prevents further corrosion of the metal.

Let's delve into the manufacturing process of shipping containers:

It all begins with a sizable sheet of steel, serving as the foundation for each container. This sheet is carefully cut into multiple pieces. To ensure cleanliness and eliminate any impurities, the sheets undergo sand-blasting and priming.

During the subsequent stages, the sheets are corrugated to enhance their strength, and the wall panels are expertly welded together. Additionally, square tubing is welded to the top of the walls for added reinforcement. The floors of the containers are meticulously crafted using sturdy and resilient wood that has been treated with a protective spray to prevent insect infestations. The floor panels and frame are produced separately. The door and corner post assembly follows suit. Firstly, the doors are installed on the floor frame, followed by the attachment of the wall panels. Subsequently, the corner posts, walls, and doors are skillfully welded in place, and finally, the roof panel is assembled and securely attached.

The concluding stages of the manufacturing process involve priming and painting the container to safeguard it against weather-related damage. Furthermore, the flooring panels are carefully varnished to shield the wood from potential water damage, and the floor is then installed within the frame. Rubber seals are fitted onto the doors to ensure a watertight seal, and the bottom of the container is made water-resistant.

By following these meticulous manufacturing steps, shipping containers are created to withstand the rigors of transportation and provide reliable storage solutions.

The weight of a container varies and depends on size of the container. Depending on their size, a shipping containers weight will vary. Standard 20ft shipping containers have a tare weight of 4,914 lbs. Standard 40ft shipping containers have a tare weight of 8,159 lbs. Standard 40ft High Cube shipping containers have a tare weight of 8,747 lbs.